Hot Stamping or Silver BOPP?

Hot stamp labels, also known as foil stamp labels, are a popular style of label printing for a variety of industries. They are particularly popular in the cosmetics, food, and beverage industries. To create these labels, we use a special process that involves heating a flatbed die and transferring a metallic or colored foil onto the label material. Occasionally, customers approach us with a specific label idea and a preference for hot stamping. That’s great! We are more than happy to make that vision a reality, but what if you could get the same look for a cheaper price? In this blog, we will discuss hot stamping and silver BOPP, and how to know which is best for your product.

What is Silver BOPP

BOPP stands for biaxially-oriented polypropylene, which is a type of plastic film that is commonly used in packaging and labeling. Silver BOPP label material has a shiny, metallic appearance that can be similar to hot stamp foil labels, but at a lower cost. This material can also be more durable than hot stamp labels, as it is resistant to water and oil, making it a good choice for products that will be exposed to these substances. Although it is referred to as “silver”, this BOPP can be flood coated with ink to give any color appearance, copper, red, green, gold, you name it!

White layers are added to silver labels, behind the art in order to dampen the metallic effect in certain places. This way, only certain elements of the label stand out as metallic. Check out our page on Building a White Layer for more information on this and a step by step guide to creating a white layer.

Price Point

One important consideration when selecting a label material is the cost. While hot stamp labels can be an effective and high-quality option, they can also be more expensive than other types of labels. In some cases, a silver BOPP label material may be a better, cheaper option for creating the final product. Hot stamping can be expensive because it involves pressing a hot flatbed die into the label material, which leaves a foil behind. Custom engraved flatbed dies for your label design can cost a few hundred dollars, but fortunately, this is a one-time expense.

The other reason the hot stamp process is expensive is because of time. In order to get the pressure between the die and the material just right, the machine must slow down significantly compared to traditional flexible metal dies used for cutting the label into the correct shape.

When to Pick Silver BOPP

Both options will provide for a stunning label, but which one is right for your product? The first thing to consider is use. If a product requires high durability or exposure to water or oil, choosing silver BOPP label material may be more suitable.

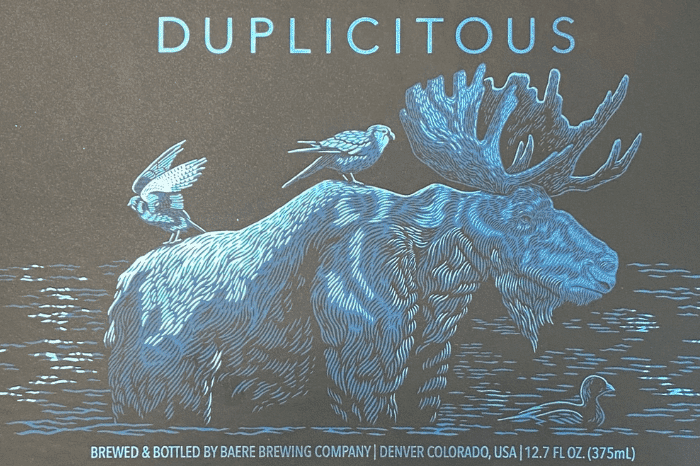

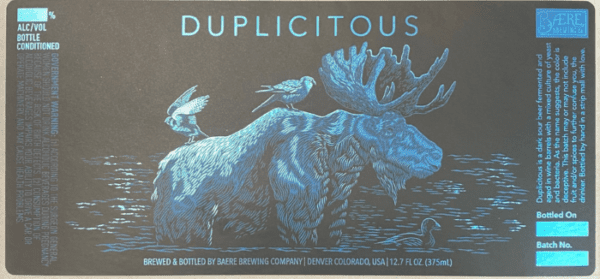

Another reason to select silver BOPP is if you have 100% ink coverage, so the substrate isn’t visible anyway. Hot stamp is ideal for wine and paper stocks as well as clear BOPP, but if you were going to select a white BOPP and hot stamp it, don’t waste your money. Silver BOPP can get you that hot stamped look at a fraction of the cost. Another reason to select silver BOPP is finish type. If you are looking for a trendy matte finish, BOPP will produce the best looking result. We do not laminate our wine and paper stocks so this type of finish is unavailable with that type of substrate.

When to Pick Hot Stamping

Hot stamp labels can be a good choice for products that require a high-end, luxury look, such as cosmetics or high-end food and beverage products, like wine. Hot stamping is the most effective method to achieve a metallic finish on non-metallic materials, commonly used on wine and paper stock materials but also applicable to clear BOPP.

Ultimately, the decision between hot stamp labels and silver BOPP label material will depend on a variety of factors, including the desired look of the label, the intended use of the product, and the budget available for labeling materials. Both hot stamp labels and silver BOPP label material can be effective options for creating high-quality, attractive labels that meet the needs of a wide range of products and industries.