Understanding Tapered Containers

Considering the shape of the container on which the label will be applied is critical when creating product labels. Tapered Containers are more common than you would think. This can present unique challenges in label application. In this blog post, we will explore how to identify a tapered container, how to measure its taper, and how a tapered container can impact a product label.

Identifying a Tapered Container

A tapered container is one that narrows towards the bottom or top, resulting in a conical or trapezoidal shape. It can be challenging to identify a tapered container at first glance, especially when the taper is subtle. One way to identify a tapered container is by looking at it from the top or bottom and observing if the diameter changes significantly from one end to the other. Another way is to roll the container on a flat surface and observe if it wobbles, or is unable to roll in a straight line due to the taper. It is important to know if your container has a taper because if a standard label is applied to a tapered container, it may appear distorted or wrinkled.

Measuring the Taper – Taper Gauge

Measuring the taper of a container is essential to ensure that the label fits properly and looks visually appealing. A taper gauge is the easiest way to measure a taper, it is a measuring tool specifically designed for this purpose. Place the taper gauge on the container with the narrow end of the gauge at the bottom or top of the container, depending on the direction of the taper. Adjust the gauge until it matches the angle of the taper, and read the measurement indicated on the gauge. This measurement will help you determine the degree of taper and ensure that your label is designed and applied correctly.

Measuring the Taper – By Hand

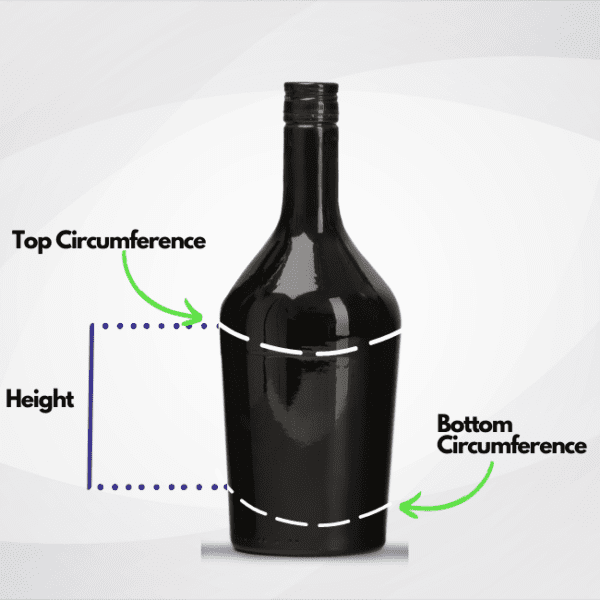

More than likely, you don’t have a taper gauge on hand. That’s okay, doing it by hand is easy. First, determine the place of your label on your container. Consider how high or low and how much area you want to cover. Next, measure the top circumference using a piece of string or a flexible measuring tape, record the number. After that, measure the bottom circumference using the same method. Then measure the height. Make sure to measure the height parallel to the container, NOT against the container. Then use an online tool such as this one from Templatemaker to generate a label template.

Professionals Please

Your product is your baby, we get it. To be 100% sure your taper is right, you can always get professional help. If you are willing to send us one of your containers, we will professionally measure it, for your perfect label! Reach out to our customer support team for more details.

Impacts on Product Labeling:

A tapered container can have significant impacts on product labeling. Due to the changing diameter of the container, a standard label may not fit properly or may result in a skewed appearance. If the label is too large for the tapered area, it may wrinkle, crease, or peel off, affecting the overall visual appeal and product branding. On the other hand, if the label is too small, it may not cover the entire tapered area, leaving gaps or exposed areas that can negatively impact the label’s durability and longevity.

To properly label a tapered container, it’s essential to consider custom label design and application techniques. To ensure a precise fit and professional appearance, it is important to tailor fit your custom label designs. Additionally, specialized label application techniques, such as using label materials with flexibility or adhesives specifically formulated for tapered surfaces, can help ensure that the label adheres properly and maintains its integrity even on a tapered container.

In conclusion, identifying a tapered container, measuring its taper accurately, and understanding how it can impact product labeling are crucial considerations for successful label application. Custom label design and specialized application techniques can help ensure that the label fits properly, looks visually appealing, and enhances the overall branding of the product. If you have a product that is packaged in a tapered container, it’s important to work with a professional label printing service that has expertise in designing and applying labels on such containers to ensure the best results.