Poly Films For Flexible Packaging and Shrink Sleeves

Poly films are a versatile category of materials widely used in the label industry, particularly for applications where durability, flexibility, and a high-quality appearance are essential. In packaging, the term “poly films” generally refers to polymer-based substrates such as polyethylene (PE), polypropylene (PP), and polyester (PET). These materials are engineered to provide a combination of strength, printability, and resistance to moisture, oils, and other environmental factors that can compromise a label or package’s integrity.

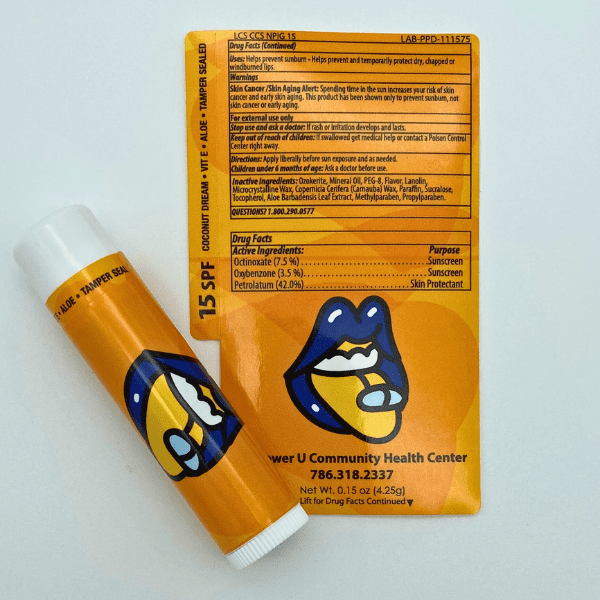

Within the label industry, poly films play a major role in one-time-use flexible packaging. A prime example is stick packs—those slim, sealed packets commonly used for single-serve products like powdered drink mixes, nutritional supplements, condiments, and personal care items. Poly films in stick packs offer excellent barrier properties, protecting contents from light, moisture, and air, while maintaining the flexibility needed for efficient form-fill-seal production. The smooth surface of these films also allows for high-resolution graphics, ensuring the package stands out while conveying important branding and product information.

Poly films are also the foundation for shrink sleeve labels, which are printed film materials that are heat-shrunk to tightly conform to the contours of a container. This packaging format is especially popular for beverage bottles, cans, and uniquely shaped products because it provides full 360-degree coverage, allowing for vibrant, edge-to-edge graphics. Beyond shelf appeal, poly films used for shrink sleeves must maintain stability during the shrinking process and offer durability for products exposed to moisture, refrigeration, or handling stress.

In both flexible packaging and shrink sleeves, poly films deliver a balance of performance and design versatility that paper-based or rigid label materials cannot match. They allow brands to create packaging that is visually striking, functional, and protective critical for standing out in today’s competitive consumer goods market.

Poly Films Deliver More Than Just Looks

Poly films have become a go-to choice for brands seeking packaging that performs as well as it looks. In both flexible formats like stick packs and full-coverage solutions like shrink sleeves, these materials deliver a balance of strength, adaptability, and visual impact. Unlike paper-based options, poly films hold up under the rigors of production, transport, and everyday use, helping products arrive in the customer’s hands looking just as intended.

Their smooth, consistent surface makes them an excellent canvas for bold, detailed graphics, allowing brand colors and imagery to shine. Whether applied to a unique container shape or formed into a single-serve packet, poly films conform beautifully while maintaining their protective qualities.

In addition to their design advantages, poly films can also serve as a protective barrier against environmental factors that can affect product quality. This makes them especially valuable for food, beverage, and health products that demand freshness and shelf stability. The result is packaging that doesn’t just look good, it actively works to preserve the product and support the brand’s reputation for quality.

Exceptional Durability

Poly films resist tearing, punctures, and moisture damage, ensuring your packaging maintains its integrity from production to consumer use, perfect for products facing shipping, handling, refrigeration, or outdoor exposure.

Superior Print Quality

With a smooth, uniform surface, poly films enable high-resolution printing and vibrant, edge-to-edge graphics. This ensures branding stands out on crowded shelves while preserving detail and color accuracy.

Versatile Applications

From shrink sleeves on uniquely shaped containers to single-use stick packs, poly films adapt to a wide range of product types, packaging formats, and production methods without compromising performance.

Strong Barrier Protection

Poly films can be engineered with barrier properties that protect against light, oxygen, and moisture, extending product shelf life and maintaining freshness, especially important for food, beverage, and nutraceutical items.

Print Your Poly Film Packaging Today!

Our Commitment to You

Columbine Label isn’t just a label printing company — we’re problem solvers dedicated to helping you achieve your business goals. When you partner with us, we promise to deliver high-quality product labels every single time.

What You’ll Get With Every Honey Label Order

Use Columbine Label Company for _______

Vinyl Labels

Vinyl labels and stickers offer exceptional durability, resisting water, UV light, and abrasion. Perfect for indoor or outdoor use, they maintain vibrant colors and strong adhesion, making them ideal for products, promotions, and long-lasting brand displays.

Natural Kraft Labels

Natural kraft labels feature an unbleached brown paper stock that delivers a warm, earthy aesthetic. Perfect for artisanal, eco-friendly, or rustic branding, they pair well with simple, bold designs and organic or handmade product lines.

BOPP Labels

BOPP labels are durable, moisture-resistant, and ideal for products that face handling, refrigeration, or outdoor exposure. Their smooth surface delivers vibrant, long-lasting print quality, making them a versatile choice for food, beverage, personal care, and industrial applications.

Paper Labels

Paper stock labels offer a classic, cost-effective option for product packaging. They’re ideal for indoor use, providing excellent print quality and a natural feel that works beautifully for everything from food jars to boutique products.

Ready to Print Your Custom Poly Film Packaging?

Gallery

Print Types